Airless Pump vs. Lotion Pump: What's the Real Difference — And Which One Should You Choose?

April 07, 2025

When you're deciding on the perfect packaging for your skincare, cosmetic, or personal care products, the choice between a traditional lotion pump and an airless pump can have a big impact on your product's shelf life, usability, sustainability, and customer satisfaction. Let's break down the differences in detail.

How Each Pump Works

◆ Lotion Pump:

A lotion pump uses a dip tube that extends into the product inside the bottle. When you press the pump head, it creates suction that pulls the product up through the tube and dispenses it onto your hand. Simple, cost-effective, and perfect for high-volume products like shampoos, body lotions, or liquid soaps.

◆ Airless Pump:

An airless pump, on the other hand, does not rely on a dip tube. Instead, it uses a piston (or airless compressor) at the base of the bottle. Every pump press creates a vacuum effect, pushing the product upwards and preventing air from entering. This technology ensures sensitive formulas stay fresh for longer.

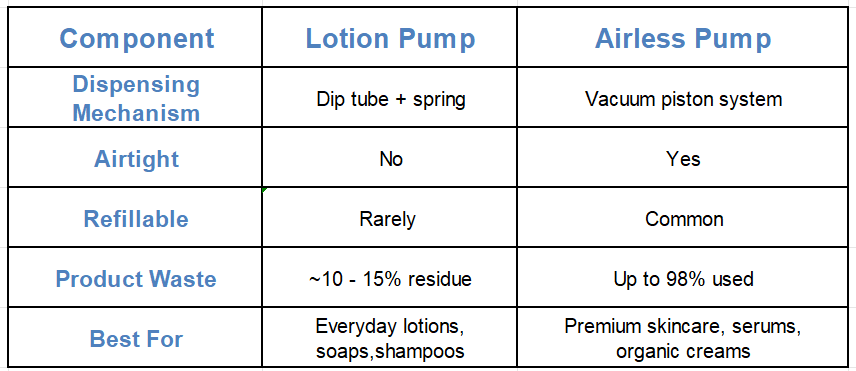

Core Components Comparison

Practical Benefits & Drawbacks

✅ Lotion Pump Pros:

Cost-effective for large quantities

Simple to produce and source in various sizes

Suitable for thicker products like conditioners or body butter

⚠️ Lotion Pump Cons:

Product can get stuck in corners or around the dip tube

Risk of air exposure leading to oxidation, especially for active ingredients

✅ Airless Pump Pros:

Longer product shelf life due to reduced air contact

Better for delicate or natural formulas with fewer preservatives

Precise dosage and less product waste

⚠️ Airless Pump Cons:

Higher unit cost

Not ideal for very large volumes due to piston limitations. May require more testing to get the pump output right for different viscosities

Sustainability Matters

More brands are turning to airless pumps as part of their sustainability goals. Many airless designs can be easily disassembled, cleaned, and refilled, supporting a circular packaging system. By contrast, standard lotion pumps are often more difficult to recycle because they combine multiple plastic parts and a metal spring.

Industry Insight:

A 2023 study by Global Packaging Trends found that 62% of new skincare launches with natural or organic positioning now use airless pump technology.

Where They're Most Commonly Used

✔ Lotion Pumps:

Family-size body lotions

Hotel amenities

Hand soaps in public restrooms

Hair care products

✔ Airless Pumps:

Anti-aging serums

High-end moisturizers

Vitamin C creams and retinol treatments

Specialty cosmeceuticals or prescription skin treatments

Key Factors to Consider When Choosing

If you're a brand owner or packaging buyer, ask yourself:

Is your formula sensitive to light or air? → Go airless.

Do you need a cost-effective solution for bulk products? → Lotion pumps are still practical.

Do you want to communicate premium value? → Airless pumps signal innovation and higher perceived value.

Will your customers reuse or refill? → Airless bottles often come in refillable designs.

✅ Expert Tip

If you're launching both premium and standard lines, consider a hybrid approach: offer everyday products like body lotion in cost-friendly lotion pumps, and your top-shelf treatments in sleek airless bottles. This approach helps you position each product appropriately while managing packaging costs.

In a conclusion,lotion pumps and airless pumps each have their strengths. The right choice depends on your product's sensitivity, your brand's sustainability goals, and the experience you want your customers to have. Done right, your packaging isn't just a container — it's a powerful way to build trust, extend shelf life, and make your brand stand out.