Where to Buy Empty Deodorant Tubes – High-Quality Twist-Up Deodorant Tubes Wholesale

April 30, 2025

Searching for quality deodorant tube packaging? Choosing the right supplier of empty deodorant tubes is key for brands and manufacturers designing solid-stick deodorants, balms, or creams. A premium deodorant tube needs to combine material safety, twist-up reliability, customization options, and ideally eco‑friendly credentials. This article answers your key questions about where and how to buy empty deodorant tubes effectively.

1. What Are Empty Deodorant Tubes?

Empty deodorant tubes are packaging containers used to hold and dispense deodorants. These tubes come in various materials such as plastic, aluminum, and eco-friendly options, making them suitable for a wide range of deodorant formulations. But why should you choose an empty deodorant tube over other packaging options?

2. What types of deodorant tube formats exist and which suits your brand?

The main formats:

● Round or oval twist‑up tubes: widely used for solid sticks and balms; support bottom/top‑fill automation.

● Gel‑specific tubes: with applicator holes for controlled dispensing.

● Push‑up paperboard tubes: eco‑friendly compostable options, ideal for green or organic brands .

Each format addresses different markets and packaging goals.

3. Where to Buy Empty Deodorant Tubes

● Online Wholesale Suppliers: Websites such as Alibaba, Amazon, and specialized packaging suppliers offer a wide variety of empty deodorant tubes. Many offer bulk discounts for larger orders.

● Packaging Manufacturers: If you're looking for bulk purchases or custom designs, going directly to manufacturers like Miya Packaging can provide personalized solutions.

● Eco-friendly Stores: Some online stores specialize in environmentally friendly packaging solutions, offering biodegradable or recyclable deodorant tubes.

4. How do typical costs, MOQs, and lead times look?

● MOQ: Standard designs may start from ~100–500 units; custom molds often require 5,000+ pieces .

● Lead times: Stock tubes in 3 days; customized tooling and branding may take 12-15 days.

● Pricing factors: Plastic PP/HDPE tubes are economically efficient; biodegradable or recycled materials may cost 20–50% more. Tooling, assembly, QC, and shipping incoterms (FOB, CIF, DDP) also influence the final unit cost .

5. What quality and regulatory criteria are essential?

Key attributes include: food‑grade or cosmetic‑safe resin (e.g. PP, HDPE), traceable material certification (FDA, EU REACH), ISO 9001/GMP audit reports, and functional testing (leak‑resistance, twist durability). For eco‑friendly options like paperboard push-up tubes, confirm compostable certification (e.g. FSC, ASTM D6400) and verify moisture barrier properties .

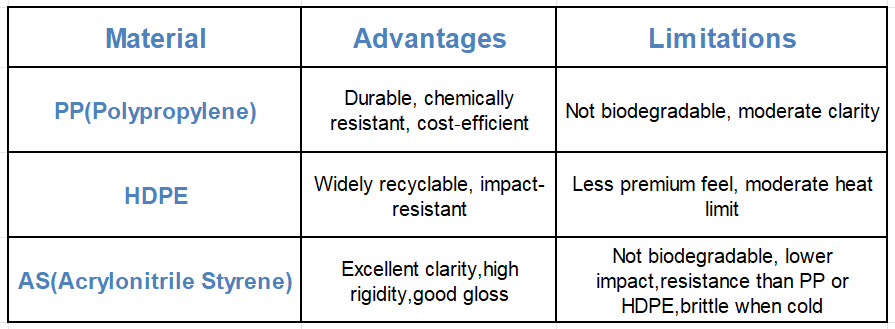

6. How do material choices impact performance and sustainability?

Here's a brief comparison table for deodorant tube materials:

7. What are common FAQs when purchasing deodorant tubes?

**Can I customize branding?**

Yes, most suppliers support color, label printing, embossed logos—but custom molds raise MOQs (typically >5,000 units) and longer production times.

**How to vet suppliers?**

Request certifications (ISO, GMP, FSC), sample orders, factory audit records, QC reports, and shipping precedents.

**What logistics & risk strategies are smart?**

Use staggered orders, multi‑supplier sourcing, flexible incoterms, buffer inventory, and diversifying shipping routes.

A well-chosen deodorant tube supplier enables brands to deliver safe, functional, and appealing packaging. Whether you opt for classic PP/HDPE twist‑up tubes or eco-friendly paperboard push‑up designs, prioritize certified suppliers, manageable MOQs, and supply reliability. Use formats and materials aligned with your branding, volume needs, regulatory requirements, and sustainability goals. This ensures your packaging not only protects the product but also enhances your brand image and consumer satisfaction.